Introduction to Food Safety

Food safety is the assurance that consuming food or its ingredients won’t cause harm when used normally.

Toxicity is the capacity of a substance to produce harm or injury of any kinds under any conditions.

Hazard refers to the potential for harm or danger that exists when a particular substance, activity, condition, or situation is present. Hazards can range from physical, chemical, biological, to environmental factors that pose a risk to health, safety, or well-being.

Food Safety (or Food Hygiene) is a scientific method or discipline encompassing a comprehensive set of protocols, procedures and regulations designed to guarantee that the entire food supply chain; from production and processing to distribution and consumption, meets rigorous standards to minimize health risks or food borne diseases.

Simply, Food Safety refers to the practices and measures taken to ensure that food is prepared, handled, stored and consumed in a way that minimizes the risk of contamination, illness or harm to consumers.

| Let’s talk about food safety to understand in easy concept: Imagine this: you’re cooking a meal, and you want to be sure that nobody gets sick from eating it. That’s where food safety comes in. It’s all about making sure that the food we eat won’t cause any harm when we prepare it, cook it, and eat it. Now, let’s break it down a bit. When we say food safety, we’re talking about a set of rules and procedures that ensure the food we buy and consume is safe for us. From the moment it’s grown or made, to when it’s cooked and served, every step of the way needs to meet strict standards. Think of it as a big system of checks and balances. We want to minimize any chance of something going wrong – like contamination or illness – by handling food properly at every stage. So, in simple terms, food safety is just about making sure the food we eat won’t make us sick. It’s all about handling, storing, and cooking food in a way that keeps us healthy and happy. |

General Principles of Food Safety

- Food safety and suitability should be ensured through science-based preventive measures, such as a food hygiene system that reduces harmful substances or various contaminants.

- Good Hygiene Practices (GHPs), including prerequisite programs, form the foundation for an effective Hazard Analysis and Critical Control Points (HACCP) system. Pre-requisite program refers to various fundamental procedures and practices which are established in workplace to create a safe and hygienic environment for food production.

- Food Business Operators (FBOs) are responsible for understanding the risks associated with raw materials, manufacturing processes, and the production environment.

- Depending on the food and processes involved, managing hazards might require a combination of Good Hygiene Practices (GHPs)and additional actions at Critical Control Points (CCPs).

- Control procedures must be scientifically validated in order to achieve acceptable food safety standards.

- Monitoring, corrective actions, verification, and documentation are essential for ensuring that control systems are effective.

- Periodic reviews of food hygiene systems should be done for any changes that may affect hazards and control.

- Depending on the food and processes involved, managing hazards might require a combination of GHPs and additional actions at Critical Control Points (CCPs).

- Control procedures must be scientifically validated in order to achieve acceptable food safety standards.

- Effective communication among every participant involved in the food chain is critical to ensuring food safety.

- Creating a healthy food safety culture requires management and employee commitment, leadership, awareness, communication, and sufficient resource allocation.

A good food safety culture is of the utmost importance for efficient food hygiene systems, as it acknowledges the importance of human behavior in providing safe food. Key elements include:

- Management and staff should be committed to producing and handling safe food.

- Strong leadership should direct / guide and involve all employees in food safety measures.

- All employees should be aware of the necessity of food hygiene.

- Clear communication throughout the food industry, including variations and expectations.

- Adequate resources to support the operation of the food hygiene system.

Basic Principles or Steps of Food Safety

- Cleaning

- Separation

- Cooking

- Storage

- Safe water and maintenance

Explanation:

- Cleaning :

Ensure cleanliness by disinfecting surfaces and equipment, maintaining high personal hygiene, washing hands, wearing clean clothes, tying hair, and using gloves to prevent germ spread. - Separation or Cross-Contamination:

There are four types of cross-contamination:

a. Cross-Contamination

b. Biological

c. Physical

d. Chemical

Prevent cross-contamination by keeping raw meat, poultry, eggs, seafood, and their juices away from ready-to-eat foods. Use separate cutting boards and plates for different types of foods, and store raw meat, fish, poultry, and eggs separately in the refrigerator. - Cooking:

Cook food items for at least 2 minutes until they reach a core temperature of 70 to 75 degrees Celsius to kill the basic microbes present in food. Use a clean food thermometer to guarantee proper cooking temperature, and thaw frozen goods thoroughly before cooking. If leftover food is not utilized within two hours, reheat it to boiling hot or chill it to 8°C or lower. - Storage or Chilling:

Cooked food should be stored in a dry, shady place i.e. away from sunlight or in a refrigerator which is set to the appropriate temperature. Also, to avoid cross-contamination, store raw meats on the refrigerator’s bottom shelves. Moreover, we should not leave food at room temperature for more than 2 hours (or 1 hour if the temperature of food is over 32.2°C).

NOTE: SFBB → Safer Food, Better Business

Food Safety Management System (FSMS) is a group of procedures, practices, and principles that manage food safety, control food safety hazards, and ensure safe and high quality foods.

Food Safety can be achieved by:

- Thoroughly cleaning and sanitizing all surfaces, equipment, and utensils.

- Maintaining top-notch personal hygiene, particularly through frequent hand-washing in workplace.

- Properly storing, chilling, and heating food, considering temperature, environment, and equipment factors.

- Implementing efficient pest management practices to control harmful pest like rat, cockroaches, etc.

- Appropriately storing and disposing of waste.

- Providing training or education to staff to ensure adherence to food safety protocols.

A Food Safety Management System (FSMS) is a planned method or system for controlling issues related to food safety inside a food establishment in order to ensure that food is safe for human consumption. It involves carefully planned methods and systems to monitor and regulate different aspects of food safety, aiming to prevent contamination and maintain high standards of hygiene throughout the food handling process.

History of Hazard Analysis Critical Control Point (HACCP)

The Hazard Analysis Critical Control Point (HACCP) system, which addresses food safety concerns, was originated with 2 important developments. Initially, W.E. Deming’s ideas, which focused on quality management, played an important role in improving the quality of Japanese products in the 1950s. During this time, Deming and others team members led the development of Total Quality Management (TQM) systems.

Furthermore in advancement of this, the Pillsbury Company, the United States Army, and National Aeronautics and Space Administration (i..e. NASA) collaborated in the 1960s to introduced the concept of HACCP. The aim of this project aims to secure the production of safe food for US space operations. Notably, NASA’s pursuit of a “ZERO DEFECTS” initiative was inspired by the requirement to ensure the safety of food consumed by astronauts during space missions.

- Pillsbury therefore introduced and adopted HACCP as the system that could provide the greater safety while reducing dependence on end-product inspection and testing. (मतलव Pillsbury Companyले Direct Final product मात्र Lastमा टेस्ट गर्नु भन्दा, अगाडी सुरु देखि नै राम्रो भयो भनी Ending Product or result राम्रो हुन्छ भन्ने कुरा finalize गर्यो )

- In the initial time or phase, the HACCP program had only 3 established principles. However, Pillsbury’s success with its implementation of HACCP system encouraged additional innovation and adoption throughout its operations and food production, solving issues such as glass contamination.

- HACCP did not remain unchanged. Several updates and petitions were submitted to improve it. In 1983, the World Health Organization (WHO) Europe formally approved (i.e. certified) its use.

The program quickly gained recognition from other organizations, including the National Advisory Committee on Microbial Criteria for Food (NACMF).

In 1985, this organization carried out a campaign to encourage the food industries to accept the HACCP program and to assist in the development of resources on HACCP principles and implementation. - 1990s to 21st Century – HACCP Throughout The Food Industry In this duration, some of the most significant improvements occured for the HACCP program.

After years of in-depth study, the NACMF issued a report in 1992 that included the seven fundamental HACCP principles and the five preliminary procedures that is established till todays date.

1960s It all begins

NASA and US Army implement food safety requirements for the US SPace program in form of HACCP System

1970’s

HACCP was presented to food industry through National Conference on Food Protection.

1980’s

(1983) – WHO Europe endorsed HACCP use

(1985) – NACMF was established and formed several publications on HACCP

1990’s

(1990) – EU makes having a HACCP plan a legal requirement for food businesses.

(1992) – NACMF presented the 7 core principles of HACCP

(1993) – Major high-risk profile outbreds that led to the mandatory implementation of HACCP.

(1994) – The International HACCP Alliance was established

2000’s

First window HACCP solution sold to online costumer

Introduction to HACCP

HACCP, or Hazard Analysis and Critical Control Points, is a systematic approach of detecting, analyzing, and controlling hazards that are important for food safety. It acts effectively, identifying and preventing possible problems before they arise, so reducing food safety hazards rather than simply reacting to them.

Hazard Analysis: Hazard analysis is the systematic process of gathering and evaluating information to identify significant hazards related to food safety.

Critical Control Point (CCP): Critical Control Points (CCPs) are specific steps in the food production process where various control measures can be applied effectively to prevent or eliminate food safety hazards or reduce them to acceptable levels.

| Example to understand HACCP |

|---|

| Hazard: Water spillage on the floor in a kitchen or workplace. Hazard Analysis: Evaluating the potential risks associated with the water spillage, such as slip and fall accidents or contamination of nearby food surfaces. Control Point: Implementing measures to prevent or minimize water spillage, such as using drip trays under equipment or regularly checking for leaks in tap or plumbing. Critical Control Point: Establishing procedures for immediate cleanup of water spillages to prevent slip hazards and potential contamination of food surfaces, ensuring staff are trained to respond promptly to such incidents. |

5 Preliminary Steps of HACCP:

- Assemble HACCP team: Establish a team of experts in food safety, production, engineering, quality assurance, and other related fields who will supervise and manage the development and implementation of the HACCP plan.

- Describe the food and its distribution: Provide complete details on the food product, such as its ingredients, composition, packaging, etc to help to know potential hazards and prevent them.

- Determine the intended use and target consumer for the product: Determine how the food product will be used and those who will be using it are i.e. consumers (e.g., children, the elderly, sick people) in order to evaluate possible hazards and improve control measures accordingly.

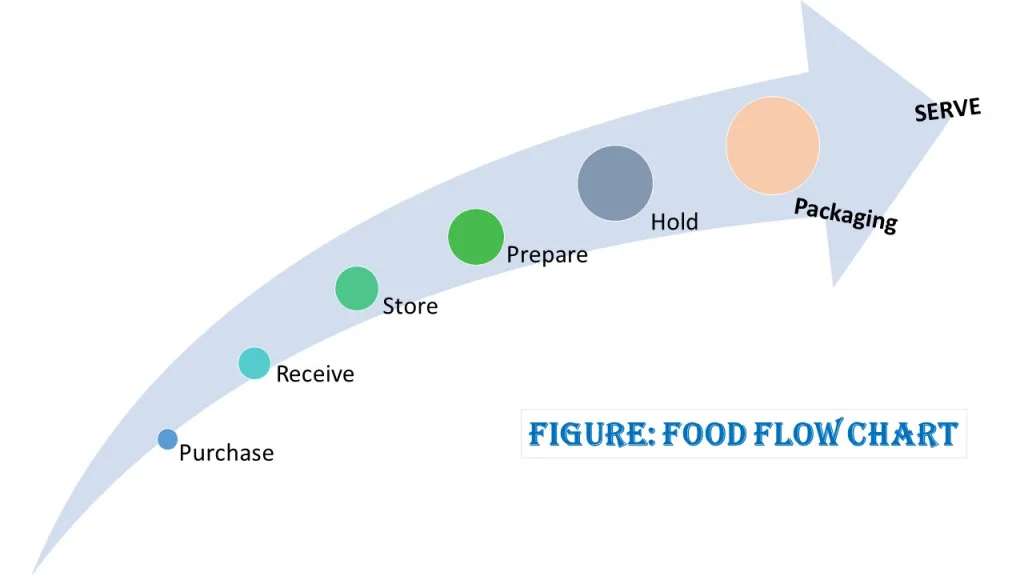

- Develop a flow diagram describing the process: To identify important control points and possible hazards, draw a complete flow diagram that shows all steps in the production process, from the first step where we bring raw materials to final product distribution till consumers.

- Verify the process flow diagram: Conduct on-site inspections, observe production processes, and communicate with the correct individuals like employees, supervisor, etc. to verify all steps and possible hazards are properly documented.

7 Principles of HACCP

Principle 1 : Conduct Hazard Analysis

→ Identify and evaluate potential hazards in food processing.

→ Prepare a flow diagram of the process from raw materials to finished product (i.e. receiving to service or from farm to plate).

→ List hazards at each step and determine preventive measures.

→ Focus on hazards with severe consequences (i.e. serious impact) if not controlled.

→ Low-risk and unlikely hazards should not be considered or focused less than higher risk hazards.

Principle 2 : Determine Critical Control Point (CCPs)

- Once the hazards are located or identified, CCPs are established where hazards can be controlled.

- Monitor CCPs more frequently than control points.

- Establish CCPs crucial for product safety.

CCP are formulated to manage each hazards after being identified.

A Control Point is any point or step where physical, chemical or biological factors of any hazards can be controlled.

A Critical Control Point (CCP) is a specific step, procedure, or stage in the food production process where control measures can be applied to prevent, eliminate, or reduce a food safety hazard to an acceptable level.

When all hazards and preventive measure have been described, the HACCP team establish the points where critical control is crucial to managing the safety of product.

Principle 3 : Establish Critical Limits

This step involves establishing criteria that must be met to prevent, eliminate or reduce the identified hazard at the CCP so that food is safe for human consumption.

- Establish minimum and maximum limits for each CCP to control hazards.

- Limits can include temperature, time, pH level, etc.

- Critical Limits can come from regulatory standards and guidelines, scientific literature, experimental, studies and consultation with experts.

Principle 4 : Establish monitoring procedures

Monitoring practice refers to the planned and systematic observation or measurement of control parameters at critical points in the food production process to determine whether the process is under control and operating as intended or not.

- Monitor CCPs to ensure control measures are effective.

- Use visual observations, measurements, and assessments.

Example of Monitoring include:

- Visual observations

- Temperature measurement

- Evaluation of time

- Measurements of pH value

- Water activity measurements, etc.

Principle 5 : Identify or establish Corrective actions

- Corrective action focus on: What to do when a food doesn’t meet the critical limit.

Example of Corrective Actions include:

- The temperature of hamburger is 60 °C after cooking (CCP)

- The critical limit is cooking the hamburger to 70 °C or hotter.

- Continue cooking until it is 70 °C or hotter.

- Or throwing out food might be a corrective actions.

- Records of all corrective actions must be maintained properly.

Principle 6 : Establishing Verification Procedures

Verification procedure must be adopted to maintain the HACCP system and ensure the system and ensure that it continues to work effectively.

Four phases of verification are needed for a HACCP plan:

- Determine that critical limits at all CCPs are sound

- Make sure that establishment’s HACCP plan is being properly implemented.

- Involve regulatory personnel and check monitoring equipment accuracy so that any changes or alternations can be detected.

- Check and verify the accuracy as well as reliability of every monitoring equipment used in the HACCP system to ensure accurate parameter measurement.

Principle 7 : Establish record-keeping and documentation procedures.

Record must be kept to demonstrate that HACCP system is operating under control and that appropriate corrective action has been taken for any deviation from the critical limits.

The following points make up the records of a HACCP plan

- HACCP Team List: Names of HACCP team along with their respective assigned responsibilities.

- Menu Item Descriptions: Description of each menu item

- Flow Diagrams: Diagrams outlining the flow of each menu item’s production process, indicating Critical Control Points (CCPs).

- Hazard Analysis: Identifying hazards related with each CCP and implementing appropriate preventive measures.

- Critical Limits: Established minimum and maximum limits for CCPs to control hazards.

- Monitoring Procedures: Description of procedures for monitoring CCPs to ensure control measures are effective.

- Corrective Actions Plans: Make sure what to do next if critical limits are not met.

- Record Keeping Procedures: Procedures for documenting all aspects of the HACCP plan, including monitoring results and corrective actions taken.

- Verification procedures: Procedures for evaluating the effectiveness of the HACCP plan and ensuring adherence to regulations and standards.

Types of Hazard

There are 3 recognized categories of hazards:

- Physical Hazards

- Biological Hazards

- Chemical Hazards

- Physical Hazards

Physical hazards include any potentially harmful extraneous matter not normally found in food.

Physical hazards present in foods are classified as:

- Glass

- Plastics

- Metals

The common sources of those agents are:

Glass: Bottles, jars, light fixtures, thermometers, gauge covers, etc.

Plastics: Bottles, jars, equipments and packaging materials

Metals: Machinery, agricultural fields, wire, staples, bangles, rings, earrings, pen and its cap, etc.

Appropriate controls like filtering, magnetic separators may need to be used to avoid these hazards.

- Chemical Hazards

Chemical hazards or contamination can be helpful and are purposefully used with some foods, such as pesticides on fruits and vegetables.

These chemicals are not hazardous if properly used or controlled.

The presence of a chemical residue may not always represent a hazard. The amount of chemical or its types may determine whether its hazard or not.

Chemical hazards can be separated into three categories:

- Unintentional or Incidental Chemical Hazards

Chemicals can become a part of a food without being intentionally-added.

For example: Environmental pollutants: Pollutants from air, water or soil such as heavy metals like lead, and mercury can be absorbed by foods.

Food Packaging Migrants: Some chemicals from food packaging materials, migrate into food. For example: Chemical from certain plastic packaging can leach into food they contain.

Food Additives and Flavoring: In proper used or contaminated food additives preservative or flavorings usage.

Allergens and Natural Toxins

Cross-contamination

- Naturally-Occuring Chemicals

These chemicals are derived from a variety of plants, animals or microorganism. In most cases, these naturally occurring chemicals are found prior to or during harvest.

Naturally occurring chemicals include: Allergens, mold toxins and naturally occurring toxins in some foods.

Allergens: The common sources of allergens in food are egg, milk, nuts, peanuts, seafood and soy. Certain varieties or species produce an allergic reaction in sensitive people.

It is particularly important that foods containing components that have these clearly identify on the label.

Mold Toxins: Molds may produce aflatoxins in some foods, most common them are apples, nuts and cereals grains. Examples are Alternaria toxins, Ochratoxin, Patulin and Vomitoxin.

Toxin Components in Food: Some foods or plants have toxic parts or chemicals naturally. Example: Mushroom, Algae, etc.

- Intentional-Added Chemicals

Some chemicals are added to food at some point during production and processing.

These chemicals are intended to be sued at safe levels, but could present a hazard if those levels are exceeded.

- Direct Additives:

- Preservatives like Sodium Benzoate and Sulfiting agents

- Nutritional additives like calcium, vitamin

- Color additives

- Indirect Additives:

- Packaging materials

- Processing plant chemicals like lubricants and sanitizers

- Biological Hazards

- Bacteria

- Virus

- Parasites

- Harmful microorganisms like insects, pests, rodents

Benefits of HACCP

Savings: saves your business money in long-term or run

Avoidance: avoids you poisoning your customer

Food safety standards: food safety standards increase

Ensure compliance: ensures you are compliant with legal law

Food quality standards are enhanced.

Organize your process to produce safe foods from start to finish (farm to plate)

Organizes your staff promoting teamwork and efficiency

Due diligence defense in court, protecting your business in legal matters.

To Consumers:

- Reduced Risk of Foodborne Illness: When businesses emphasize food safety through HACCP implementation, consumers benefit from lower risks of foodborne illness.

- Increased consumer confidence in food supply: Consumers gain increased confidence in the safety and quality of the food supply chain, knowing that food safety standards i.e. HACCP principles are being followed.

- Increased Food safety awareness: HACCP implementation enhances consumer awareness about the importance of food safety standards, allowing them to make better choices and advocate for safer food options.

- Improved quality of life: Safer food contributes to improved public health and socio-economic well-being, enhancing overall quality of life for consumers.

To business industry or organization:

- Saves Cost: Reduces the production costs by reducing waste and product recalls .

- Customer safety: By adhering to HACCP principles, business organizations can avoid the risk of poisoning their customers, thereby safeguarding their health and maintaining trust in their brand.

- Compliance or Follow rules, regulation and laws: HACCP ensures that organizations follow food safety laws and regulations, saving them from penalties and reputational damage.

- Improved quality standards: HACCP helps improve food quality standards by focusing on preventing various hazards throughout the production process, resulting in safer and higher-quality products.

- Helps to run business smoothly: HACCP helps you organize your processes and staff, making everything run more efficiently.

To government:

- Improved Public Health: HACCP helps to enhance public health outcomes by lowering the risk of foodborne illnesses and related healthcare expenses.

- Cost Reduction on public health: By preventing foodborne diseases, governments can save on healthcare expenses associated with treating sick individuals.

- Facilitation of International Trade: Compliance with HACCP standards facilitates government negotiations and participation in international trade agreements by showing commitment to global food safety standards.

- Increased community confidence on food supply: When governments enforce HACCP standards, it increases public confidence in the safety and reliability of the food supply chain, leading to greater trust in regulatory authorities.

- Risk Management: HACCP helps governments identify and manage risks connected with food production and distribution, allowing for more proactive steps to protect public health and reduce possible food safety issues.

Other Food Safety Tools Like HACCP System

- ISO 22000

- Good Manufacturing Practices (GMPs)

- Food Safety Management Systems (FSMS)

- Hazard Analysis and Risk-Based Preventive Controls (HARPC)

- Total Quality Management (TQM) and so on.

Frequently Asked Questions

Important Questions

- Explain the importance of food safety to hospitality industry.

- Define Critical Control Point (CCP) with example.

- How can you implement HACCP in catering industry? Describe benefits of implementing HACCP.

- Define food safety.

- Define HACCP. What are benefits of HACCP implementation in food industry?

- Define hazard and give examples.

- Define critical limit.

- Explain principles of HACCP.

- When did HACCP start? Explain its history in brief.