4.1. Introduction to Fabrics

Fiber is a thin thread of a natural or artificial substance, especially one that is used to make a cloth or rope. Or, A material which is available in the form of thin and continuos strand is called fibre.

The natural fibers that were used throughout the history of mankind were silk, cotton, wool and flax. Then artificial fibers were created that include rayon, nylon, acryilic and polyster. Manufactured fibers are made from raw substaces through being processed in factories.

They are placed into 2 groups according to their composition and characteristics. i.e.

- Cellulosic

- Non-Cellulosic

Cellulosic is obtained from tree or plant. Example: Rayon, linen, Jute, Cotton, Ramie and Sisal. All of the remaining manufactured fibers are non-cellulosic, which means they are entirely chemically-based. Example: Nylon, Olefin, Acrylic, Polyester and Spandex.

Fabric is a cloth or other material produced by weaving, knitting or felting fibers. Fabrics are used for making things such as clothe, curtains and sheets. The most common use of fabric is for clothes. For example, Denim is the fabric used to make jeans. All clothes are made of some type or combination of fabrics.

All fabrics are made with artificial or natural tiny hair-like fibers. Fabric may either be cloth that we produce by weaving or knitting or structures of a building.

But some are produced by non-woven process such as braiding, felting, and twisting. These fibers are mixed by twisting them together making a yarn. The yarns are woven, knitted or they are ironed onto the fabric.

4.2. Types and Classification Of Fibers

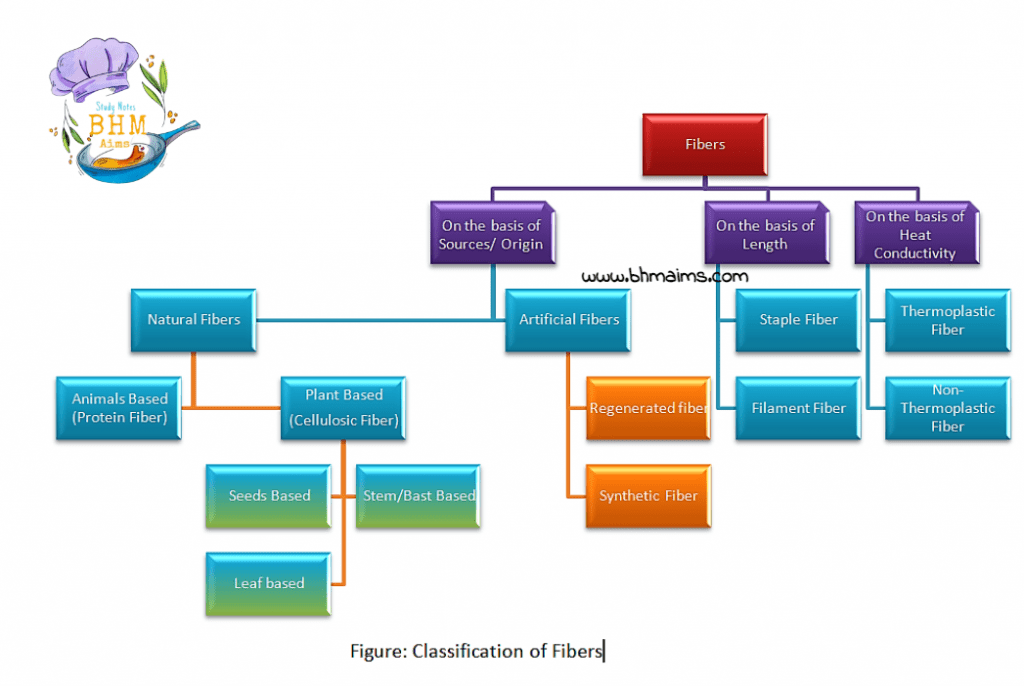

Fibers are classified mainly into 2 categories. i.e.

- Natural Fibers

- Artificial Fibers

CLASSIFICATION ON BASIS OF ORIGIN / SOURCES

A. NATURAL FIBERS

All the fibers obtained from nature i.e. plants or animals are known as natural fibers. Example: cotton, Wool, Linen, Silk, etc. Fibers obtained from plants are called cellulosic fibre Example: Cotton and linen. The fibres that come from animal sources are known as protein fibres. Example Wool and Silk.

Sources of some natural fibers:

| Sources | Fibers Obtained |

| Cotton pods and balls | Cotton |

| Silkworm Cocoons | Silk |

| Sheep | Wool |

- Plant Fibers

Plant fibers are generally composed of cellulose, often in combination with other components such as lignin. Example: Cotton, Hemp, Jute, Flax, Ramie, Sisal and Bagasse.

Plant fibers are classified according to their sources in plants. i.e.- Bast or Steam Fibers – Derived from the fibrours bundles in the inner bark of plant stems.

- Leaf Fibers – Runs lengthwise through the leaves of monocotyledonous plants.

- Seed Fibers – Hair fibers, such as cotton

- Cotton: Cotton fibers are seed fibers. We get cotton fiber from the seeds of plants. Cotton fibre is very soft to touch and is fluffy. It is used in bath towels, tetile industry, pharma industry, etc.

Advantages of cotton:- Cotton is easily dry cleaned.

- Cotton is durable since the fiber is strong.

- we feel comfort during summer by wearing cotton dress.

- Cotton is good conductor of heat.

- They are suitable for all body types which means its non-allergic.

- Cotton: Cotton fibers are seed fibers. We get cotton fiber from the seeds of plants. Cotton fibre is very soft to touch and is fluffy. It is used in bath towels, tetile industry, pharma industry, etc.

Disadvantages of Cotton:

- Cotton is flammable.

- Damp cotton may be affected by mildews.

- Cotton fabrics take long time to dry rather than synthetic fabrics.

- Cotton weakens and turns yellow after repeated expose to sunlight.

- Jute: Jute fiber is obtained from the stem of the jute plant. Hence, jute fiber are bast fibers. It is a long, shiny and soft fiber. It is stronger than fibers such as cotton. It is one of the most affordable fibers. It is used in the twine, rope, bags doormats, etc. The strong threads made from jute fibers are used worldwide in sack cloth.

Jute is grown in the rainy season. Jute requires alluvial soil and standing water for growth. Jute plant is harvested when it is in the flowering stage.

- Flax: Like jute fibers it is also a bast fiber. These fibers are also 2-3 times stronger than cotton fibers. It is naturally smooth and straight. The fiber is used in making liunen cloth which is used as clothing, for bedsheets and table linen. They absorb and release water quickly, making linen comfortable. It is a cellulose polymer.

- Hemp: Like jute annd flax fiber, it is also a bast fiber. Hemp fiber conducts heat, dyes well, block UV light and has natural anti-bacterial properties. It is used increasingly in ear panels andd fiber boards and cotonize for clothing.

- Coir: It is also a seed fiber like a cotton fiber. We get it from coconut. It is the fibrous part of coconut which lies between the hard sheel of the coconut and outer green covering.

It is used in making doormats, brushes, mattress, packaging, bedding and flooring. It has uses in agriculture and horticulture. - Abaca: It is leaf fiber composed of long slim cells that from part of the leaf supporting structure.

In conclusion, as plant fibers are natural fibers, they are eco-friendly and easily accessible. Also, they are health beneficial like anti-cancer.

- Animal Fibers

Animal fibers consist largely of proteins. Example: Silkworm silk, Spider silk, Wool, Sinew, Catgut, animal hairs such as Cashmere, Mohair, and rabbit hair, etc.

- Wool: Wool is an animal fiber produced from the several animals furs of Caprinae family. Wool is commonly associated with sheep, although itmay aslo be obtained from other species such as goats, rabbits, and alpacas. The diameter of a strand of wool can range from 17 micrometers (mm) to around 35 micrometers (mm).

- Characteristics of Wool:

- It is a poor conductor of heat; it traps the heat, and make us feel warm.

- It is elastic in nature, can be stretched and wrinkled but it regains its shape, this feature makes it resistant to tearing.

- It dries fast.

- It is light weight in nature.

- It can be dyed in various different colours.

- It is soft.

- Characteristics of Wool:

- Silk: Silk is a natural, protein filament produced by silk worm. Fabrics made from silk are soft, fine, smooth, lustrous, warm and stronger than wool. It is used for formal wear and is called “Queen of the fibers”.

Properties of Silk:- It is the strongest of all natural fibers.

- It is shiny and soft.

- It can be easily dyed into various colors.

- Since, it doesn’t conduct heat and is a good insulator it remains cool in the summer an warm in the winter.

- It absorbs moisture.

The practice of silk rearing is often reffered to as sericulture.

5 notable examples of fabrics that are derived from animal fibers:

| Fibers obtained | Obtained from |

| Silk | derived from silkworm (the fiber is obtained from the silkworm cocoon) |

| Cashmere | derived from fur of cashmere goat |

| Shearling | derived from fur of shearling lambs |

| Shahtoosh | derived from fur of Tibetan antelope |

B. Artificial fibers:

The fibers which are made in laboratories using chemicals are known man-made fibers or artificial fibers. They are created by the process of polymerization, which involves combining monomers to make a long chain or polymer.

Some of the most common fibers, which are used in daily life are polyster, nylon, acrylic, etc. Such fibers isn’t elastic, durable, tough and strong as much as natural fibers.

It can be further classified on 2 major types. i.e.

- Synthetic Fiber: These are those fiber in which man has performed the entire operation of fibre-production without allowing the nature to manufacture the fibre-forming subsance.

These fibers are formed by the polymerization of monomers. It’s disadvantage is they cling to the body of the wearer and may cause sparks and explosions or fires. The pilling of staple fibers is also disadvantages. But they show good sunlight resistance compared to natural fibers.

Example: Polyster, Acrylic, Trivinyl, Nylon, etc. - Regenerated Fiber: These are fibers that can neither directly found from nature nor can be produced by using chemicals. These fibers are re-generated from natural material using some chemical process.

Example: rayon, bamboo fibers, modal, lyocell, etc

Some of the major fibers are:

- Nylon: It is thermoplastic silky material that can be melt or processed into fibers, films or shapes, Nylon is extensively used for stretch covers. The fibers is knitted and provides greater elasticity. This may be blended with wool. Nylon fibers are quite tough and abrasion resistant. They are used to make ropes, linen, tires, tent and so on.

- Polyster: A strong lightweight and durable synthetic fiber, invented in the year 1938. It is a man-made fiber derived from coal and petroleum. Its molecule is long, strong and stable. It is resistant to wrinkles, abrasaion and chemicals.

- Rayon: It is a synthetic fiber sometimes used as a blend with natural fibres. It is lustrous, smooth, and cool and absorbent but is weak in nature. It wrinkles very easily. Because of its close resemblance with silk, it is also called “Articial silk ” or “Art silk”. It is used as a summer wear. These fibers are thermoplastic in nature; i.e. they are heat sensitive and soten & melt on application of heat.

- Acrylic: Acrylic resenbles wool in its properties. It is made from acrylic a plastic component. It is extremely soft, light weight and very close to wool. Dralon acrylic is suitable for velvets. Acrylics are tough, washable and long lasting. They are colour fast and easy to maintain. Often used in sweaters, blankets and outer warm clothing items.

- Viscose: Viscose is a semi-synthetic type of rayon fabric made from wood pulp that is used as a silk substitute, as it has similar drape and smooth feel to the luxury material. It is made from tree wood pulp, like beech, pine and eucalyptus, but can also be madde from bamboo.

It is lightweight. It is very light weight fabric that doesn’t stick to body. So it’s optimal warm weather clothing. Whille the material looks like silk, it feels like cotton. Also, viscose can hold dye without fading. It is affected by mildew. - Spandex: Stretchy fiber that is often used in sports-wear, swimmer and other clothing items that require flexibility and a snug (i.e. tight) fit.

CLASSIFICATION ON THE BASIS OF LENGTH

- Staple Fiber:They are short length fibers whose lenngth runs in centimeters (cm) qnd inches. They are natural fibers – cotton, flax, wool are examples of it

- Filament Fiber: They are long length fibers whose length runs in meters and kilometers. For example: All synthetic fibers like nylon, rayon, polyster and the only natural filament fiber is silk.

ON THE BASIS OF HEAT CONDUCTIVITY:

- Thermoplastic Fiber: It is a plastic polymer material that becomes plliable(i.e.flexible) or moldable at a certain elevated temperature and soldifies upon cooling. Hence, it means they lose their shape on heating and regains on cooling.

Example: Polyster, acrylic, nylon, teflon, etc. - Non-Thermoplastic Fiber: Non-thermoplastic fibers are those that don’t soften or melt with heat but will in most cases scorch or burn if the temperature is sufficiently high.

Example: Viscose nylon

4.3. Characteristics Of Fibers Fabric Used

Fibers and fabrics are connected to each other. Fibers are converted into fabrics by the process of weaving, knitting, spreading and blending, etc. Some characteristics are as follows:

- Abrasion Resistance: The ability to withstand wear and tear from repeated rubbing is known as abrasion resistance. From good to poor: Nylon, linen, acrylic, cotton, wool(coarse), silk. wool(fine), rayon and acetate.

- Elasticity and Elongation: Elongation is the amount of stretch or extension that fibre will accept. Breaking elongation is the amount of stretch that occurs to point where the fibres break.

All fibers can be stretched- but they don’t have the same breaking point or the ability to recover from the stretch. The ability to recover from the stretching state is important when planning a project- clothing needs that to return to its orginal shape after the normal wear. Recovery may not always be immediate and the ability. Higher recovery percentage to lower percentage: Wool, silk, rayon, cotton, ramie, flax or linen. - Heat Sensitivity / Thermal Properties: Meaning wet and dry heat. Silk, wool and all protein fibers should never be boiled, simmering is the best for washing and dyeing. Cotton, linen and other cellulose fibers are quite heat resistant and can be boiled safely.

- Flammability: Wool offers the greatest resistance to fire, and other protein fibers are usually self-extinguishing. Cellulose fibers continue to glow after they are removed from the flame. Synthetic fibers vary, but range from acrylic that is so hot that it can ignite a combustible material if it drips on it, and others that are or have vinyl cyanide or vinyl chloride whose fumes are toxic.

- Warmth: Yarns can be spun (i.e. spin) to trap air and therefore be warmer. Woolen spun yarns being in that category. Retention of heat from high to low: Silk, angora, wool, cotton, ramie, flax.

- Wrinkle recovery / Shrinkage: When relaxed fibers are used there is less tendency to wrinkle. Blocking all your yarns, make it necessary to always block you finished pieces and properly finished hand-woven pieces have a better wrinkle recovery. From good to poor: Wool, silk, rayon, ramie. flax.

- Moisture regains / Absorbency: All fibers tend to absorb moisture when in contact with the atmosphere. The weight of moisture present in a textile material is expressed as a percentage of its oven-dry weight (dry weight obtained by drying at 105-110 degree celsius). Natural fibers have higher moisture content compare to synthetic fibres have higher moisture content compare to synthetic fibres. Moisture content compare to synthetic fibres. Moisture of a fiber has a positive influences on clothing comfort of its fabric, penetration of the chemicals and dyestuffs, elongation at break, etc. On the other hands, low moisture regain helps the fabric for easy washing and drying.

- Weight: From heaviest to lightest: Cotton, flax, ramie, rayon, hemp, polyster, wool, silk, acrylic, nylon

- Pilling: Pilling appears on garments when groups of short or broken fibers become tangled together in a tiny knot or ball.

Short fibers work loose from the yarn and tangle around the ends of neighbouring fibers. They form little fuzzballs, which are held in place by longer fibers in the yarn. Proper fulling of wool reduces or eliminates pilling.

Resistance from good to poor pilling: SIlk, flax, cotton, wool, acrylic, polyster, nylon. - Strength: Strenth is also one of the most important characteristics of textile fiber. Strength of any material is derived from the load it supports at break and is thus a measure of its limiting load bearing capacity. Weak fibers can’t produce a strong yarn.

Length of individual fibers, and amount of twist in the yarn can help determine the strenth of the yarn can help the strength of the yarn, but some fibers are stronger than others. In order from strongest: Flax, hemp, silk, nylon, polyster, cotton, acrylic, wool, rayon. - Uniformity: It means the evenness of the individual fibers in length and diameter. A fiber possessing this property can produce reasonably even threads. This is also important in connection with the strength of the resulting yarn. The more uniform the yarn, the stronger the yarn.

- Color: Most natural fiber have some colour i.e. for example: silk is yellow to tan. Wool is brownish tint. Cotton is creamy white or brown. This is a natural coloring matter and requires to be removed before subsequent wet processing treatment such dyening and printing.

The removal is done with bleaching agents. Most of the synthetic fibers too have a slight creamy or yellowish color. therefore, they must be bleached or boiled and stripped off their color by some chemical process in order to produce a fiber/yarn as white as possible.

4.4. Selection Criteria Of Fabrics

It is small part of project but have great impact on client satisfaction. That’s why it is more important to make responsible selection. Major criteria of fabric selection are pointed below:

- Cost of buying and maintenance: Laundering cost comes next to labour cost. Synthetics require lesser temperature and shorter programs for laundering when compared to cotton. “No iron blends” do not require ironing.

- Color: Major point of attraction is the choice of color and textures to the textiles. It remains in first priority for good impression considering people wants. Color, pattern and texture in fabrics can bring about character to a room. But one should not forget ease of maintenance. Coloured fabric must be checked for dyed stability. Fabric dyed at yarn stage (vat dyed) is definitely more color fast than the ones dyed at the fabric stage.

Dark colored fabrics show dust and lighter marks, whereas light coloured shows dirt and stains easily. these will be less apparent in a medium toned fabric.

Also, color must be easily available when replacements are required. - Style: Almost an indefinable in the design process, style is so important making sure that fabrics work. They carry off the look the designe is trying to create that they send a message about the room or the home.

- Size: Purchasing linen should be of right size. It is extremely important as wrong sizes can affect appearance and even hamper operations, besides avoidable wastage and loss of money.

- Pattern and texture: A patterned fabric can hide marks. Abstract patterns will not hide marks as much as mottled patterns. Large pattern can make a large area look filled and vice versa. Also, less pattern fabric is commonly found for formal settings. A more open texture can collect dust & dirt.

- Comfort: Comfort is affected by feel (texture) and weight of the fabric or cloth. Any fabric which is in contact with the skin must be absorbent. Cottons have a very high absorbency when compared to synthetics.

- Durability of fabric: The durability or life expectancy of the fabric should be substantial. This can be achieved by keeping following things in mind :

- Thread count: It is measure of the number of warps and wefts per square inch of the fabric. Ideal thread count is 180 sq. per inch.

- Weight of fabric: Lighter the fabric, easier to handle and takes less time to dry. This is particularly true for bed and table linen as they are handled and worked frequently. For soft furnishings, the heavier fabric is preffered as they are better for durability, texture and fall. The weight of fabric may be epressed in ounces/yard or pound/yard.

Example: Bed linen is about 36 ounches/yard. - Flames retardancy: Wool is a naturally flame retardant. Synthetic fibers which are made flame retardant are also available.

- Resistance to pest: Mildew is a type of fungus that causes stains especially on cotton and linen. Moth larvae, on the other hand, eat into the cloth so cloth should be resistant to these pests.

- Shrinkage resistance: This refers to the shrinkage percentage of a particular fabric after washing. Fabric may shrink after 2-3 wash. Synthetics don’t shrink whereas natural fibers shrink 6-8 % unless they have been sanforized. Wool losses its shapes if not carefully laundered.

- Abrasion resistance: It is the resistance of fabrics to the surface wear and tear. Denim has high abrasive resistance therefore more durable it is.

- Thermal insulation / power: Thermal insulation properties or warmth of fabric is measured in units called togs. these must be checked in blankets. Drapery should also help to maintain the temperature of a room.

- Strength: It depends upon several factors like types of fabric used, type of weave and closeness of weave also affect fabric strength. Check the strength of selvedges by tugging (i.e. pull hard) at it.

- Amount of dressing: Process if adding starch to make the fabric look more stiff and durable is known as dressing. So even loosely woven fabric appears to be stiff and firm when starched. Hold linen in hand and rub it over a black surface. If you see white dust or starch particles falling out it denotes poor fabric. Higher the amount of dressugn lesser will be the durability and cheaper will be the fabric. Look at the fabric under a magnifying glass to check amount of dressing.

Most Important Questions (Exam View)

- What do you mean by fiber and fabrics? Explain its classification and characteristics in details.

- What is fiber? Explain the characteristics of natural and man-made fiber with suitable examples.

- How are fibers classified? Discuss each with example.

- Define:

- Fabrics

- Fiber

- Yarn

- Staple fiber

- Pilling / Bobbling of fabric

- Ginning

Answer: Ginning can be defined as the process of obtaining cotton fibres by combing. It was done by hand before but now it is done by using machines.