Introduction, structure of meat, effect of heat on meat cookery, Processing of whole

animal (Pre-slaughter, slaughter, Post slaughter), Meat grading (Quality & yield grading)

Introduction to Meat Fabrication

Meat fabrication refers to the process of breaking down a whole carcass or large primal cuts into smaller, usable, and market-ready portions. It includes cutting, trimming, boning, tying, and portioning meat into standardized sizes required for retail, wholesale, or culinary use.

While “butchering” usually describes the slaughtering and primary breakdown of the animal, meat fabrication focuses more on creating specific cuts that are ready for cooking or selling—like steaks, roasts, fillets, chops, cutlets, etc.

Why Is Meat Fabrication Important?

Proper fabrication:

- Improves the value of the meat by producing desirable cuts

- Helps chefs choose the right cut for the right cooking method

- Reduces waste and improves cost control

- Ensures uniformity of portion size for restaurants or retail

It bridges the gap between the animal carcass and the final meat dish.

General Principle of meat fabrication:

To achieve good-quality cuts and minimize waste, certain rules are followed:

- Separate tender cuts from tough cuts

- Separate thick portions from thin portions

- Cut across the muscle fibers

- Separate high-value cuts from low-value cuts

- Remove excess fat, sinew, and connective tissue

- Maintain clean and precise knife cuts

- Prioritize maximum yield with minimum waste

- Keep tools and workspace sanitized

- Handle meat at safe temperatures to prevent spoilage

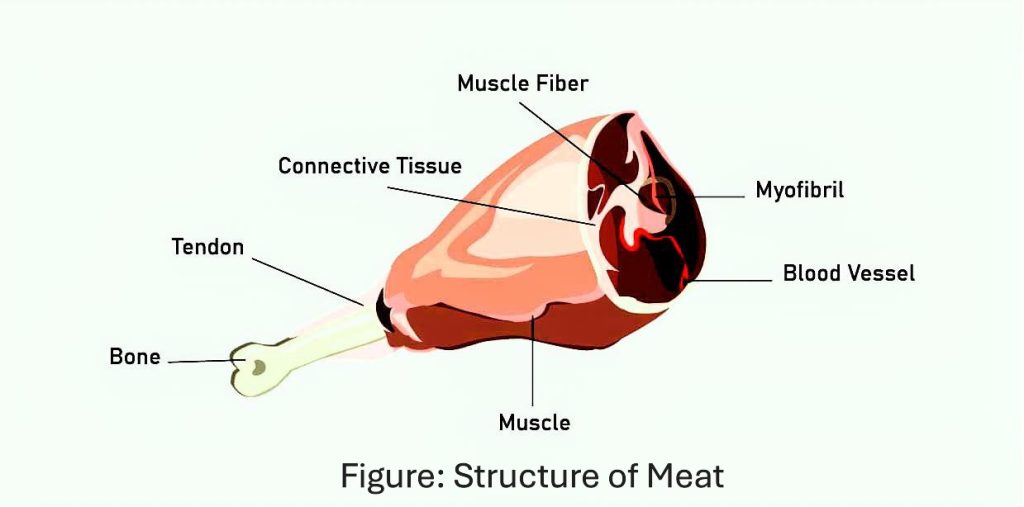

Structure of Meat

Meat is composed of muscle tissue, connective tissue, fat, bones, blood vessels, and water.

- Muscle Fibers: Long, cylindrical cells that contract to give meat its texture. Bundles of fibers are called fascicles, held together by connective tissue.

- Connective Tissue: Supports and binds muscle fibers. Main types:

- Collagen: Tough; softens with slow cooking.

- Elastin: Strong, elastic; does not break down easily.

- Reticulin: Fine network around fibers.

- Fat (Adipose Tissue):

- Intramuscular fat (Marbling): Within muscles; improves tenderness and flavor.

- Subcutaneous fat: Under the skin; protects and insulates.

- Bones: Provide support, shape, and attachment for muscles; marrow inside bones can be used in cooking.

- Blood Vessels: Supply nutrients and oxygen to muscles; responsible for meat color and some flavor characteristics.

- Water: Makes up 70–75% of fresh meat; affects juiciness and weight.

Slaughtering Process and Techniques

In many European countries, slaughterhouses are traditionally known as “abattoirs.” A well-functioning slaughterhouse must have:

- Proper equipment

- High sanitary standards

- Adequate space for handling and storing meat

- Skilled professionals trained to follow humane and systematic slaughtering procedures

Slaughtering is the act of killing animals and preparing them for human consumption.

The method used varies across the world depending on:

- Religion (e.g., Halal, Jhatka, Kosher)

- Tradition

- Cultural practices

- Government laws and regulations

Regardless of the method, modern slaughtering aims to:

- Reduce stress and pain for the animal

- Ensure hygienic handling

- Produce safe, high-quality meat

Stages of Animal Slaughtering

The slaughter process is carried out in a sequence of well-defined stages to ensure efficiency and safety:

- Pre-slaughter Handling

(Caring, transporting, resting, inspecting the animal before slaughter) - Slaughtering Process

(Stunning, bleeding, skinning, evisceration, carcass splitting) - Post-slaughter Handling

(Cleaning, chilling, grading, storage, inspection)

A. Preslaughter Handling

Before an animal is slaughtered, several careful steps are followed to ensure animal welfare, food safety, and high-quality meat production. The pre-slaughter stage focuses on inspection, preparation, and handling of the animal under hygienic and controlled conditions.

- Inspection of animal:

Before slaughtering, every animal must be examined by trained veterinary inspectors. This inspection is a legal and safety requirement in most countries.- Ensures the animal is free from diseases, infections, injuries, or abnormalities

- Confirms the animal is fit for human consumption

- Only healthy animals are approved and marked for slaughter

- Preparing the animal for slaughter:

Once declared healthy, the animal undergoes several preparation steps:- Resting (Lairage)

Animals are kept in pens—clean, dry enclosures—for at least 24 hours. Animals are given plenty of clean drinking water, but movement is restricted to keep them calm.

Purpose of resting:- Maintains normal heart rate and body temperature

- Reduces stress, resulting in better-quality meat

- Minimizes bacterial growth

- Allows proper blood drainage during slaughter

- Helps shorten the rigor mortis period (meat becomes tender sooner)

- Fasting

Food is withheld for 12–24 hours before slaughter. Little water is still provided to prevent dehydration.

Benefits of fasting:- Cleans the intestines and reduces the amount of undigested food

- Lowers the risk of bacterial contamination during evisceration

- Improves meat quality

- Prevents contamination of the carcass with gut contents

- Washing

Before entering the slaughter area, animals are washed in a tunnel with warm water sprays from all sides.

Washing helps:- Remove dirt, mud, manure, and other surface contaminants

- Improve hygiene during slaughter

- Reduce bacterial load on the skin

- Stunning

According to animal welfare regulations, animals must be stunned into complete unconsciousness before slaughter. This ensures a quick, humane, and relatively painless death, and makes handling safer for workers.

Purpose of Stunning:

Stunning is performed for two major reasons:

a. To induce immediate insensibility

(animal becomes fully unconscious and cannot feel pain.)

b. To immobilize the animal sufficiently

( Prevents movement during the sticking (bleeding) stage, allowing smooth and complete blood drainage.)

Simply, Stunning helps the animal lose consciousness quickly and allows proper bleeding to produce high-quality meat.

- Resting (Lairage)

Methods of Stunning

Different techniques are used depending on the facility and type of animal:

- Knocking

- An old method where the animal is hit on the head with a heavy hammer (between the eyes).

- Aimed to make the animal unconscious.

- Outdated and not recommended due to welfare concerns and inconsistent results.

- Carbon Dioxide Stunning (CO₂ Chamber)

- Animals are placed in a chamber filled with high CO₂ concentration.

- Gas causes unconsciousness within seconds.

- Not preferred because weak animals may die prematurely instead of just being stunned.

- Captive Bolt / Cartridge Pistol

- A pistol-like device is placed firmly on the forehead between the eyes.

- A rubber or metal bolt shoots forward to damage the brain momentarily, causing immediate unconsciousness.

- Widely used in cattle and larger animals.

- Electrical Stunning (Electric Tongs)

- The most common and effective modern method.

- Tongs are placed on both sides of the animal’s head (usually between the ears).

- A current of 60–70 volts (or adjusted according to animal size) is passed through.

- Renders the animal unconscious for 15–20 minutes, long enough for proper bleeding.

- Water Bath Stunning (For Poultry)

This one is super common in poultry plants. It’s basically the poultry version of electric tongs. Used because it’s fast, cheap, and works for large-scale operations.- Birds are hung upside down on a conveyor.

- Their heads pass through an electrified water bath.

- The electric shock causes instant unconsciousness.

B. Slaughtering

- Sticking

- Sticking is performed immediately after stunning the animal.

- A knife with a 6-inch blade is used while the animal’s heartbeat and blood pressure are still high, which ensures efficient bleeding.

- Religious methods:

Halal: Practiced by Muslims; involves cutting the throat in a prescribed way.

Jhatka: Accepted by Sikhs and some Hindus; involves a single blow to sever the head from the body using a heavy butcher’s knife.

- Bleeding

- After sticking, animals are hung by their hind legs or heads downwards.

- The blood is drained as completely as possible to:

- Improve meat texture and tenderness.

- Ensure better shelf-life.

- Collected blood is directed to:

- A blood-containing tank, or

- A processing area for further use or disposal.

B. Post-Slaughtering

- Flaying and Cleaning

- Flaying: High-pressure air is blown between the skin and flesh to separate them, then the skin is carefully removed

- Cleaning / Evisceration:

- Stomach and intestines are removed, inspected, and sent to the tripe section.

- Offal (edible internal organs) is separated and sent to the offal section.

- Carcass Handling: The carcass may be:

- Split into hindquarters and forequarters, or

- Kept whole and sent to the butcher’s section.

- Ageing

- Rigor Mortis:

- After slaughter, muscles stiffen due to chemical changes in the flesh.

- This stiffening is called rigor mortis.

- It naturally disappears over time:

Large beef carcasses: ~7 days

Lamb: ~4 days

Smaller carcasses like veal or pork take less time. - Softening occurs due to natural enzymes in the meat.

- Ageing Process

- Carcasses are hung on hooks in cold rooms at 1–2°C to allow natural tenderization.

- Ageing is controlled holding, not just refrigeration. Proper conditions prevent spoilage while meat becomes tender.

- Rigor Mortis:

| Rigor Mortis: The natural stiffening of muscles after slaughter due to chemical changes in the muscle tissue. Ageing: The controlled storage of meat at low temperatures after slaughter to allow natural enzymatic tenderization and improve flavor. |

Methods of Ageing

- Wet Ageing

- Meat is cut into smaller portions and vacuum-packed in air- and moisture-proof packaging.

- Protects against bacteria and mold, and prevents weight loss due to drying.

- Vacuum-packed meats must be refrigerated.

- Dry Ageing

- Large cuts of meat are stored unwrapped, exposed to air on all sides.

- Temperature, humidity, and air circulation are strictly controlled to avoid spoilage.

- Moisture loss can be up to 20%, depending on the size of the cut and duration of ageing.

| Feature | Dry Ageing | Wet Ageing |

|---|---|---|

| Packaging | No packaging; meat exposed to air | Vacuum-packed in air- and moisture-proof bags |

| Environment | Temperature, humidity, and airflow strictly controlled | Refrigerated storage only |

| Moisture Loss | Up to 20% due to evaporation | Minimal; moisture retained by vacuum pack |

| Cost / Loss | Higher due to weight loss and longer storage | Lower; less weight loss, easier handling |

| Typical Use | Large cuts, specialty beef | Most wholesale meat cuts, everyday use |

Meat Grading

Meat grading is the process of evaluating carcasses and classifying them into groups based on their quality, yield, and value, helping in marketing, pricing, and distribution. Grading is strictly regulated by the laws of the country of origin.

- Quality Grading

Quality grading focuses on the eating quality of meat. It assesses characteristics that affect tenderness, juiciness, and flavor. Higher quality grades indicate superior eating experience, making the meat more desirable to consumers.

Factors considered in quality grading include:- Tenderness

- Juiciness

- Flavor

- Marbling

- Maturity

- Texture, firmness, and color of lean meat

- Yield Grading

Yield grading evaluates the amount of saleable meat a carcass provides. It measures the quantity of lean meat available in boneless or semi-boneless cuts and the amount of exterior fat.

Key points of yield grading include:- Weight of saleable, lean cuts

- Amount of external fat

- Grading scale ranges from Grade 1 (highest usable meat, least fat) to Grade 5 (lowest usable meat, more fat)

| Feature | Quality Grading | Yield Grading |

|---|---|---|

| Purpose | To determine the eating quality of meat | To determine the amount of usable meat |

| Focus | Tenderness, juiciness, flavor, marbling, maturity, texture, color | Quantity of saleable lean meat, amount of external fat |

| Evaluation Basis | Sensory and physical characteristics of meat | Weight and proportion of saleable cuts |

| Scale / Grades | Usually letter-based or descriptive (e.g., Prime, Choice) | Numerical scale (Grade 1 to Grade 5) |

| Focus | Customer Customer-focused – ensures satisfaction with taste and quality | Business/profit-focused – maximizes usable meat and profitability |